BY MANUFACTURING SAFE AND RELIABLE ELEVATORS, WE ARE BUILDING TRUST WITH PEOPLE AROUND THE WORLD.

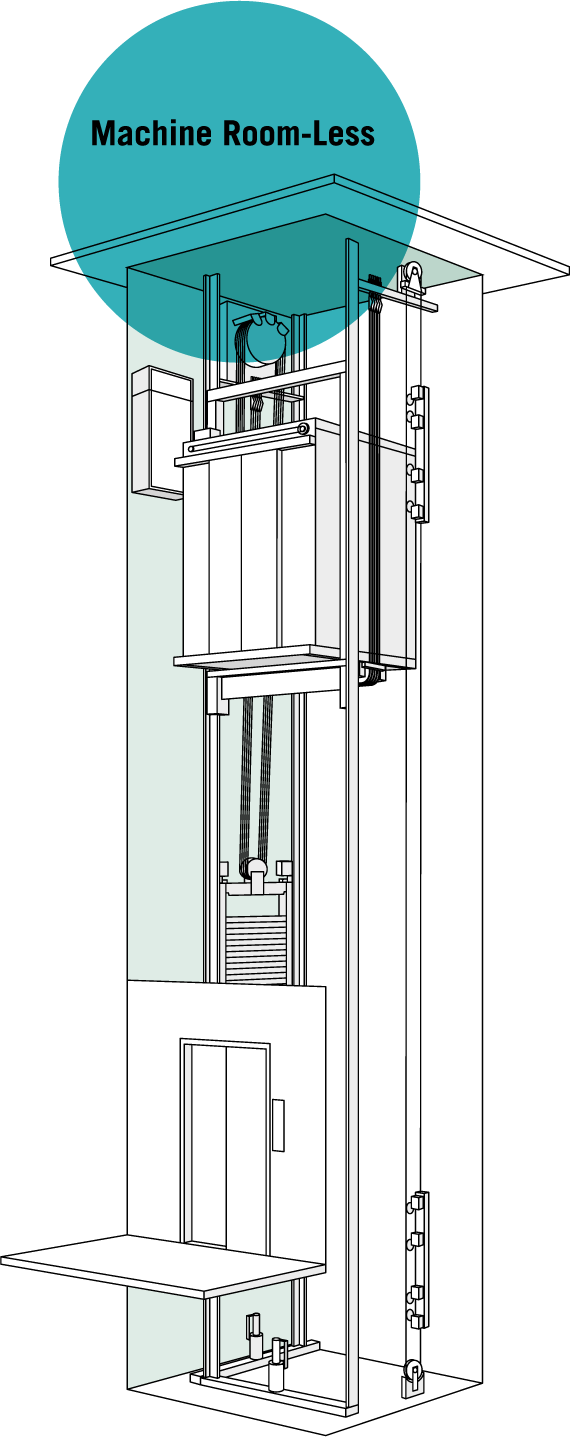

Fujitec’s “Global Common Components” are used in the ZEXIA and Rexia models. The quality of components, such as traction machines, elevator controllers, and operating fixtures, is contrilled through Fujitec’s integrated system of global quality management. Elevators with the same high quality will be provided by Fujitec’s global production base under “Made by Fujitec” concept.

MAIN SPECIFICATIONS

Capacity

450, 630, 800, 1000, 1200, 1275, 1350, 1600, and 2000 kg

Speed

1.0, 1.5, 1.75, 2.0, 2.5 mps

Number of Served Floors

40 Stops or Less

Travel Height

90 m or Less

Control Method

Variable Voltage Variable Frequency (WVF) controlled by distributed 32-bit Microcomputers.

Traction Machine

Gearless Machine with Permanent Magnetic Synchronous Motor (Permanent Magnet Gearless Motor)

Control Method

Variable Voltage Variable Frequency (WVF) controlled by distributed 32-bit Microcomputers.

Traction Machine

Gearless Machine with Permanent Magnetic Synchronous Motor (Permanent Magnet Gearless Motor)

Types of Elevator Operation

1-Car or 2-Car Selective Collective Operation or Group Control Operation for 3 to 8 Cars in a Bank

Door Operation System

Permanent Magnetic Motor controlled by WVF

Door Opening Type

(The elevators of 450kg load capacity are equipped with 2-panel side opening doors as standard.)

Safety & Reliability

Ecology

In ZEXIA and REXIA elevators, gearless traction machines with permanent magnet synchronous motors (also known as Permanent Magnet Gearless machines) assure low power consumption. Also, the electric power regenerative unit equipped between the elevator controller and the power supply saves the electrical energy consumption in the building. Fujitec

contributes to global society by providing for ecology-conscious products, drawing on its 70 years of knowledge, experience and technologies in manufacturing elevators.